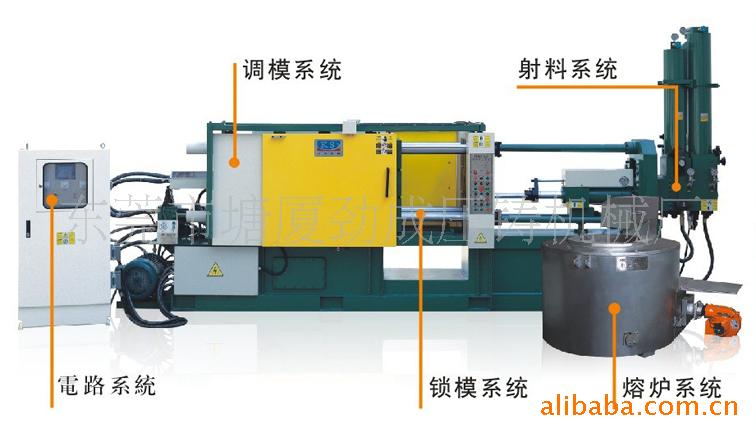

| 详细介绍: KSC(400T)冷室压铸机

调模系统:采用全方位齿轮液压调整,确保定、动模板永久的平行。

射料系统:采用了目前国外最先进前置压射回路,有效提高压射速度和减短系统的建压时间。

电路系统:采用三菱、欧姆龙触摸屏集成控制,使套机稳定性更高,报警内容提示可快速排除故障。

锁模系统:模板和机铰采用高强度球墨铸铁坚固耐用,哥林柱采用特殊工艺制作。

熔炉系统:选用设备:柴油炉、煤炉、电加热。

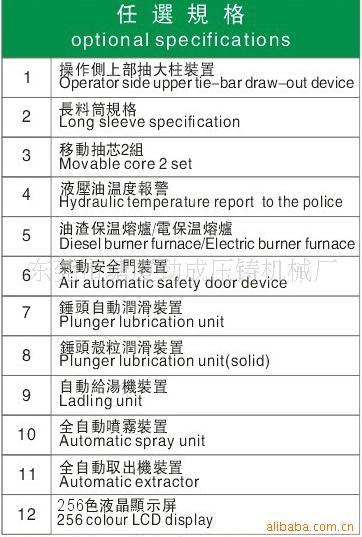

KSC(400T)冷室压铸机标准规格与任选规格

冷室镁合金压铸机技术装备 COLD CHAMBER TECHNOLOGY

1、高应答、高可靠性,提高射出性能快速填充回路从而降低能耗。另外采用活塞密封件方式不需保养,而氮气不会泄露。

2、提供二段式慢压射及快压射速度选择,适合生产各种产品要求。

3、四段压射系统,可生产高精度产品。

1、Piston Accumulator as standard equipment the piston accumulator system of toshiba machine keep in check pressure loss and making it possible to be high response and high reliability.

2、Tow phase speed can be selecte in slow injection speed and high injection speed.

3、Four stages injection system.

1、采用世界名厂液压元件,工作稳定、可靠、寿命长;

2、采用高性能低噪音的高低压双系统,节省能量及提高生产效益。

3、所有油制以低压直流电DC24V启动控制,使机械安全性及稳定性高。

1、Provided with dismountable blanking bucket to fit with customer's working condition and convey device may be arranged.

2、Adopt high function and low noise high twin pump, saving energy and produce high benefit.

3、All hydraulic valves are controlled in DC 24 volts. They increase machine safety and steadibity of the operation.

1、三重油液过滤,确保油液清洁,减少油压元件卡死,磨损,延长寿命;

2、采用高性能低噪音的高低压双系统,节省能量及提高生产效益;

3、水冷式油冷却器,冷却效率高,稳定维持油温。

1、Three stage hydraulic filler up maintain a good working conditions of hydraulic valres.

2、Adopt high function and low noise high twin pump, saving energy and produce high benefit.

3、Water-cooling type oil cooler with high cooling efficiency can maintain stable oil temeperature.

1、提高了其射出部刚性的同时,能有效地防止射出时的振动及射出平衡度的偏移,而且可以应对短料筒(任选)规格,适应用户的各种需求;

2、快压射系统和增压系统由独立活塞式储能器组成,大大减低维修及机械运作成本,安全可靠,提供高速和稳定性的压射系统。

1、Rigidity of the shot end is increased, holding the C-frame securely against vibrations during shots, and maintaining the shot alignment. Furthermore, if facilitates from the short sleeve to the long sleev (optional), meeting the customer's various needs.

2、The use of piston type accumulator has advantages over conrentional bladder type because the piston type is more reliable, accurate, maintenance free and has a longer life. Moreover ,the accumulator is equipped with a horizontal connection unit which enables steady and safe injection operation.

特殊金属材料料筒

与原来的H13材料比是原来的5—10倍寿命维持稳定的品质。

Germet sleeve

Compared with conventional sleeves of H13 materials, the life span is 5 to 10 times longer it contributes to stabilization of quality.

冷室压铸机熔炉

1、高效快速、省油、环保;

2、采用瑞典名厂喷火器,操作容易,火力稳定,可靠耐用。

Cold chamber melting pot

1、High performance economical oil environ mental protection.

2、Oil injection burner from famous swedish maker is adopted, It's easy to operate and it is reliable and durable with stable firepower.

KSC400-T冷室镁合金压铸机技术参数表

项目 Projects

|

单位 |

KSC400-T |

锁模力 Clamping force

|

KN |

4000 |

锁模行程 Clamping Stroke

|

mm |

560 |

| 模板尺寸 Moulrling board |

mm |

970X970 |

| 哥林柱内距 Inner space between tiebbar |

mm |

620X620 |

| 哥林柱直距 Tiebar diameter |

mm |

130 |

| 调模厚度 Mould thickness |

mm |

300-700 |

| 工作油压 Working oil pressure |

kfg/cm2 |

140 |

| 射料力 Injection force |

KN |

150 |

| 射料位置 Injection place |

mm |

0,-175 |

| 增压力 Increase force |

KN |

450 |

| 射料行程 Injection stroke |

mm |

520 |

| 锤头推出长度 Hammerhead ejection length |

mm |

220 |

| 锤头直径 Hammer diameter |

mm |

60/70/80 |

| 射料重量 Injection weight |

kg |

2.7/3.6/4.7 |

| 铸造压力 Foundry pressure |

kgf/cm2 |

1444/1070/815 |

| 铸造面积 Foundry acreage |

cm2 |

275/378/500 |

| 最大铸造面积 Maxdmum foundry acreage |

cm2 |

1000 |

| 顶出力 Ejector stroke |

KN |

180 |

| 顶出行程 Ejector stroke |

mm |

125 |

| 油泵电机 Oil pump mechanical |

HP/KW |

30/22 |

| 油箱容量 Oil box cqpability |

L |

850 |

| 机械重量 Machine weight |

kg |

15000 |

| 机器外形尺寸(长X宽X高)Appearance and size of machine |

mm |

5900X1650X2560 |

|

![]() 暂无相关下载

暂无相关下载